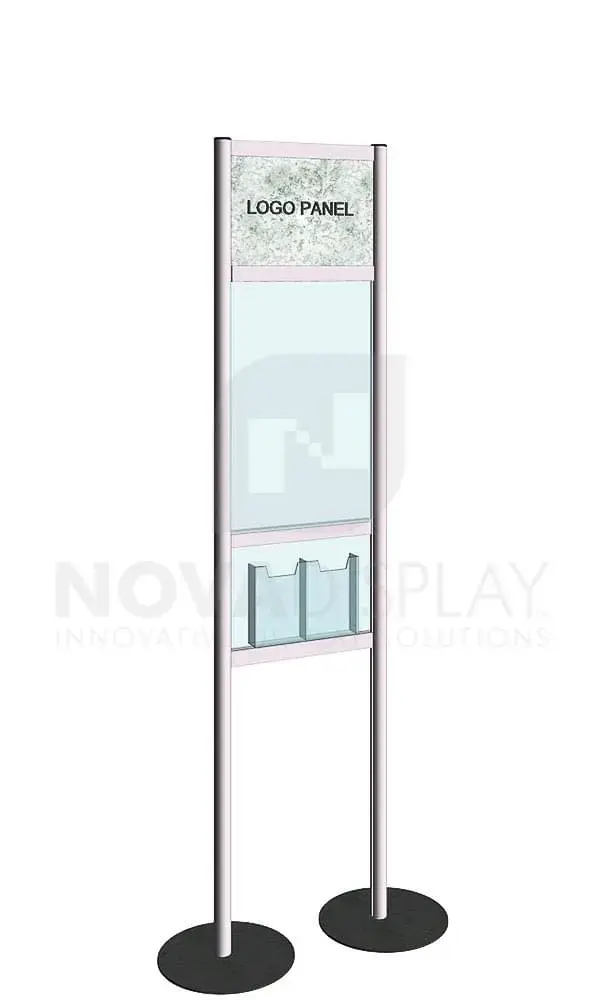

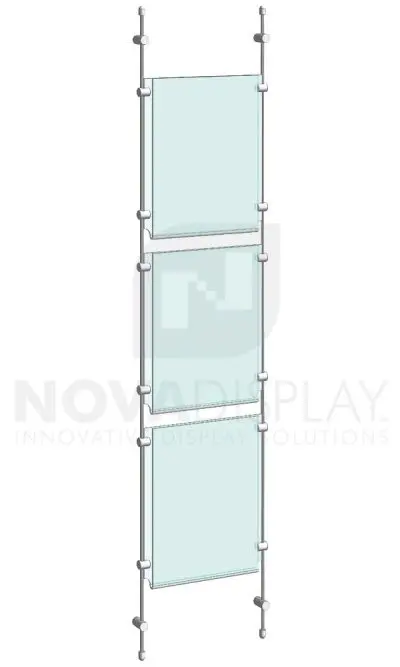

Stack-on Free-Standing Display Kit #KFST-004

From: $830.13 Original price was: $830.13.$803.84Current price is: $803.84.

Stack-on Display Stand / ST Series with custom logo panel, one set of non-glare acrylic sandwich panels to hold 14″W x 22″H format poster inserts and one or two acrylic leaflet dispensers for 3.5″W x 8.5″H tri-fold brochure inserts.

Product Description

Stack-on Display Stand / ST Series with custom logo panel, one set of non-glare acrylic sandwich panels to hold 14″W x 22″H format poster inserts and one or two acrylic leaflet dispensers for 3.5″W x 8.5″H tri-fold brochure inserts.

FIXING TYPE:

Floor Standing (Aluminum Frame / Single Section)

HARDWARE:

MR1100/72″/+D1 – Vertical Extrusion (2 ea)

PH1035/14″/L/C – Horizontal Extrusion (4 ea)

370-180 – End Cap for MR1100 (2 ea)

625 RND12UNI – 12″ Dia. Round Floor Base (2 ea)

652 108 – Insert Block (2 ea)

ACS-806 – 72″ Clear Gasket (2 ea)

ACCESSORIES:

14ASP-1114LG – Acrylic Logo Panel (1 ea) – Size: 14.25”W x 11.25”H

18ASP-1422NG/ST – 1/8″ Non-glare Acrylic Panel (2 ea), Insert Size: 14”W x 22”H

18ALD-2-3585/ST – 1/8″ Clear Acrylic Leaflet Dispenser for Tri-Fold Brochures (1 or 2 ea).

*Use 2 back-to-back for double-sided stands.

AVAILABILITY: 3-7 Bus. Days (Fabrication and Delivery Time)

FINISHES: Stand framing comes in anodized aluminum with floor bases in silver vein/powder coat paint as standard. All accessories are made of high-quality clear/non-glare acrylic.

CUSTOMIZATIONS: To customize your own Stack-On Display Stand / ST Series Kit, please send us a short description or graphical attachment. All custom orders are subject to a minimum order requirement, please contact our sales representatives for more information at 800-753-9688.

INSTALLATION NOTES: Assembly required.

* Most small orders are shipped via UPS Ground. Large orders or oversize items will be palletized and shipped via motor freight. Additional Freight & Handling Surcharge may apply. We suggest ordering a few units at once in order to save on shipping cost.

We offer Multiple Unit Discounts (Mix & Match). Call 800-753-9688 for details.

Attributes

Logo Panel

| Logo & Info Panel Sizes | |

|---|---|

| One or Two-Sided | |

| Material Thickness | |

| Compatibility | |

| Finish | |

| Availability |

Acrylic Leaflet Dispenser for STACK-ON Display Stands – Double Pocket. Insert Size: 3.5"W x 8.5"H Tri-Fold. (with 1/8" base)

| Panel Size | |

|---|---|

| Insert Size | |

| Width | |

| Load Option | |

| Load Limits | |

| Compatibility | Use with cable/rod display systems or stack-on display stands |

| Weight | |

| Mounting Options | |

| Finish | |

| Availability |

ALUMINUM END CAP – MR SERIES

| Extrusion End Caps | |

|---|---|

| Dimensions | |

| Extrusion Compatibility | |

| Weight | |

| Mounting Options | |

| Materials | |

| Finish | |

| Availabilty |

Printing Services for Posters & Graphics / Satin Polyester Film

| Print Size | |

|---|---|

| Graphic Thickness | |

| Compatibility | |

| Finish | |

| Availability |

Cleaning & Handling of Acrylic Display Products

When caring for acrylic accessories, it’s crucial to avoid using incorrect cleaners, as they can cause harm. Never use cleaners containing ammonia, glass cleaners, or furniture polish such as Fantastik, Tilex, Windex, or Clorox, as they can damage your acrylic. Instead, use mild soap and water or products specifically recommended for cleaning acrylic, such as Novus or other Rated Anti-Static Cleaner and Polish for Plastics. When cleaning, use micro-fiber disposable low lint cloths designed for acrylic and other plastics, and avoid using a dry cloth or your hand. Using the wrong cleaner can lead to immediate or delayed damage, weakening structural joints and causing cracking. During installation, handle acrylic with care to prevent cracking.

Product Limitations

Acrylic is not as rigid as glass or metals. Large, flat acrylic sheets, if insufficiently supported, may deform permanently due to continuous loads or even their own weight. Acrylic sheet can be used at temperatures from -30°F (-34°C) up to +190°F (+88°C), depending on the application. It is recommended that temperatures not exceed 160°F (71°C) for continuous service, or 190°F (88°C) for short, intermittent use. Components should not be exposed to high heat sources such as high wattage incandescent lamps, unless the finished product is ventilated to permit the dissipation of heat. Acrylic sheet is a combustible thermoplastic. Precautions should be taken to protect this material from flames and high heat sources.

Acrylic/Plastic Cleaning Kit

Acrylic/Plastic Cleaning Kit

Cleaner & Polisher — cleans and brightens acrylic and all hard plastic surfaces. Leaves a shiny polished surface that resists dust and fingerprints. Contains no abrasives or harsh chemicals. Cleans, glazes, and eliminates static charge all in one operation. Recommended for: Acrylic, Plexiglass, Lexan, Vinyl, Glass, and all hard plastics. Use disposable or reusable cleaning cloths.

Installations Instructions

How to Install KFST-004 Stack-on Display Stand / ST Series ❯ DOWNLOAD THE PDF HERE.

Related products

-

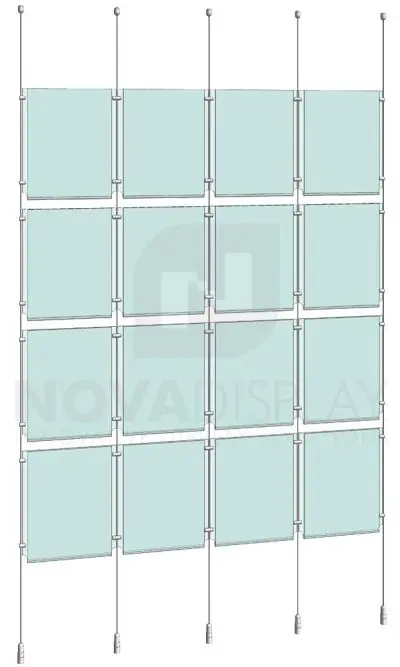

Cable Suspended Easy Access Poster Display Kit #KPI-105

$551.80 – $1,316.28Original price was: $551.80 – $1,316.28.$466.58 – $1,188.39Current price is: $466.58 – $1,188.39. -

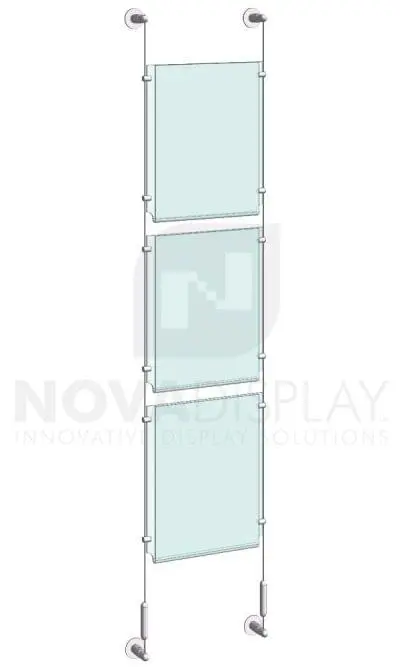

Cable Suspended Easy Access Poster Display Kit #KPI-009

$194.10 – $292.44Original price was: $194.10 – $292.44.$167.87 – $258.20Current price is: $167.87 – $258.20. -

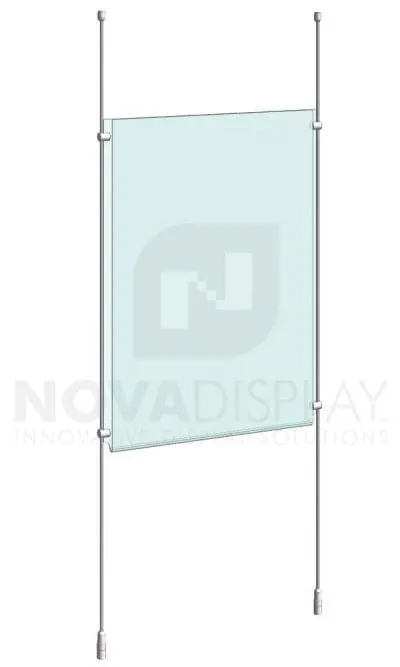

Rod Suspended Easy Access Poster Display Kit #KPI-016

$205.41 – $594.84Original price was: $205.41 – $594.84.$189.15 – $571.42Current price is: $189.15 – $571.42. -

Rod Suspended Easy Access Poster Display Kit #KPI-012

$252.50 – $350.84Original price was: $252.50 – $350.84.$228.55 – $318.88Current price is: $228.55 – $318.88.

SEARCH BY KEYWORD/SKU

STORE CATEGORIES

- Specials & Promo Discounts

- ★ Clearance & Overstock Items

- Wall Display Ideas | Products

- Wall Displays | Project Details & Downloads

- Product Bundles | Bulk Savings

- Display Solutions & Design Ideas

- Display Systems & Installation Accessories

- Cable Display Systems

- Rod Display Systems

- Rail/Track Display Systems

- Sign & Panel Support Systems

- Aluminum Modular Display Systems

- Accessories for Cable/Rod & Rail

- Acrylic Products

- Signware Products & Accessories

- Hardware & Miscellaneous

- Other Products & Services